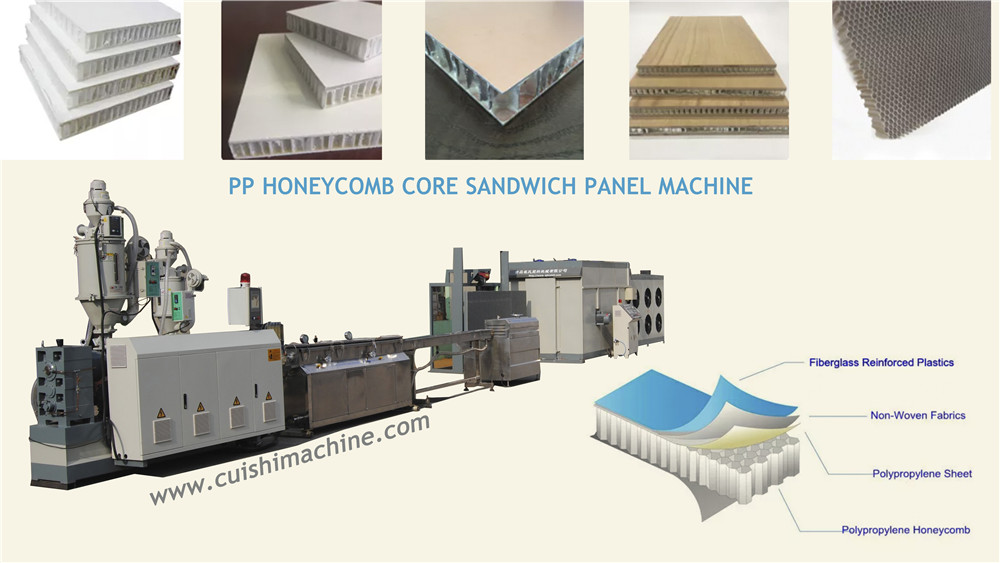

PP hollow sheet line

Our company major in all kinds of PP hollow corrugated sheet making machine.

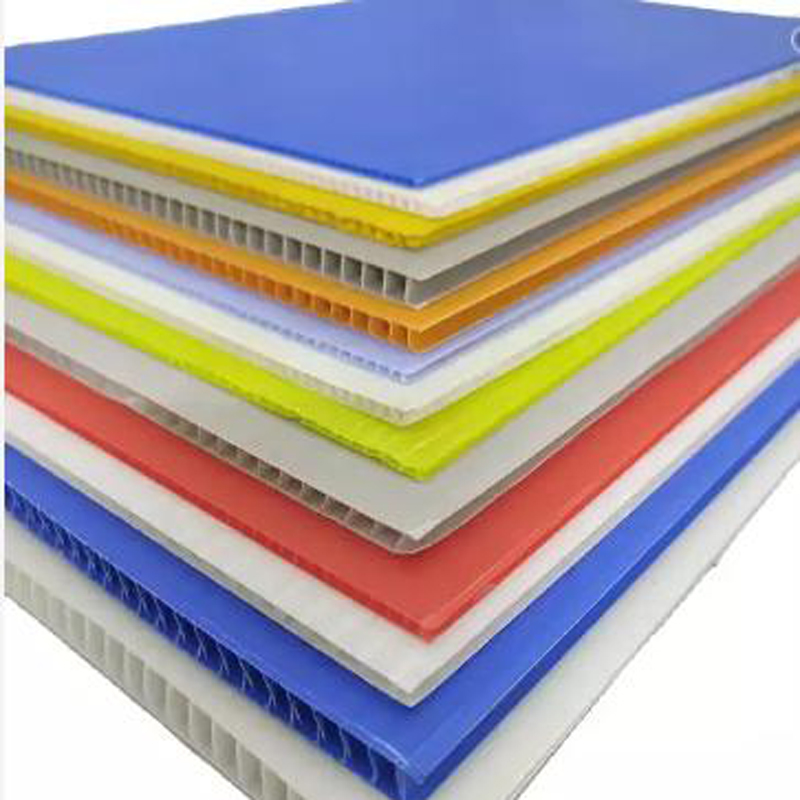

We have the machines for the PP hollow grid plate width from 1200mm to 2400mm and thickness from 2mm to 12mm. We have different model production line,such as the 1400 type PP hollow sheet extruder machine, 1800 type PP corrugated panel extrusion line, 2400 type PP hollow corrugated board making machine, And for each model,we have co-extrusion type for customer choose. The co-extruder type can use 20%-60% filler match for reduce the cost, so our customer can produce the cost competitiveness sheet with good quality.

| Name of Commodity | Quantity(set) |

| SJ120/36 PP hollow grid sheet line

(production width 2200mm, 2-6mm .output 400-450kg/h, speed 1-6m/min) |

1 set

|

| The following are the auxiliary machines | |

| Die-cutting machine (flat pressing) | 1 set |

| 3-color printing press | 1 set |

| Corona Treater | 1 set |

| AUTOMATIC MIXING MATERIAL and color | 1 set |

| Waste edge recycling machines

scrap recycling crusher |

1 set |

| SWP360 crusher | 1 set |

| 20HP cooling fan chiller | 1 set |

| Ultrasonic welding machine for hollow board | 1 set |

| Semi-automatic nail box machine | 1 set |

| Manual box stapler | 1 set |

| Baler | 1 set |

PP/PE hollow sheet is light and high strength, moisture-proof, good environmental protection and re-fabrication performance and can be used into the reusable container, packing case, clapboard, backing plate.

TECHNICAL SPECIFICATION OF PP HOLLOW SHEET PRODUCTION LINE

I. Main technical parameters:

1. Suitable material: PP

2. Extruder Output: 400-450kg/h

3. Power: 3-phase, 380V, 50Hz

4. Product specification:

Production valid Width: 2200mm

Thickness: 2mm-6mm

THE MACHINE POWER :280KW

| big ginger box 4MM | 850G | |

| fruit tray 3MM | 550G |

Ⅱ. Detailed specification of the line:

SJ90/35 PP hollow grid sheet line

( with width 1220mm, thickness 2-6mm .output 240kg/h, speed 1-6m/min)

Machine list:

l Automatic uploading machine 1 set

l SJ-120/36 single screw extruder 1 set

l Hydraulic pressure automatic screen changer 1 set

l Grid plate die(as per sample provided) 1 set

l Vacuum calibration set 1 set

l The first hauling off machine 1 set

l Thermal drying equipment 1 set

l Cold air setting equipment 1 set

l The second hauling off machine 1 set

l Board cutter machine 1 set

l Transportation system (stacker) 1 set

l PLC touch screen control system 1 set

Detailed specification of the line:

Automatic uploading machine: Taiwan SHINI product

Automatic feeder: Taiwan SHINI product SHD series hopper dryers are designed for drying non-hygroscopic plastics granules SHD series blows hot air from bottom cone via a shade separator. Standard features include P.D. temperature control (drying up to 150oC), hinged hopper for easy cleaning, hopper base assembly, hopper lid prepared for easy mounting of hopper loader. Options include 24-hr timer, insulated hopper, dust collector,hot air recycler, take-off box, mobile stand etc

1. SJ120/36 single screw extruder

This extruder is a new type of screw design developed by the company. The structure is suitable for the research and development of low-cost products. It has the characteristics of good plasticization, good dispersion and high output.

Barrel: barrel is made of special steel alloy, and is equipped with aluminum thermal foil with air cooling system

Gearbox: gears are made of steel alloy with heat treatment and are finished with surface precision grinding. By using oil injection cooling system, it reduces noise when operating under high RPM and enhances the life span of gears

Motor: AC motor, selected famous brand products. Controlled by Japanese Fuji frequency converser.

Control system: Adopt selected high quality and famous brand products from Europe, Korea and Japan manufactures. Machine works more stable and longer working-period.

1.1 Model SJ-120/36

1.2 High efficiency screw

Diameter 120mm

L/D 36:1

Material 38CrMoAlA

Surface Treatment Nitrided and Polished

1.3 Barrel

Material 38CrMoAlA

Inner Surface treatment Nitrided, ground

Heating method 380V, 60HZ

Heating power 49KW

We use special screw type , you can use 30% recycling crushed pp and 70% virgin raw material

1.4 Gearbox

Material of the house QT200

Gearbox type ZLYJ250

Gear type Helical gears

Material of the gear 20CrMnTi

Heat treatment of the gear surface Quenching

Material of the axes 40Cr

Bearings Imported high bearing

1.9 Electricity equipment:

“china famous brand SINEE ” inverter for variable frequency speed modulation

OMRON/delta intelligent meters are adopted for the temperature control system. They feature double-passage, PID data self-determination, digital communication, temperature alarming and open heating circuit indication, etc.

Melt pressure and temperature measure service are one sets.

The switchgear cabinet is designed and manufactured as per Siemens/schenider/delixi standards

2. Hydraulic pressure automatic screen changer 1 set

Keep the machine working and clean out the flotsam in time.

Hydraulic pressure driving

Double net hydraulic screen changer

Cylinder stroke : 250mm

Working oil pressure : 10-20mpa

Motor power : 4kw

Melt pressure sensor 2 sets

3.Grid plate die(as per sample provided) 1 set

Mould material steel with high quality p20

Mould width 2400mm

Number of temperature control zones 11 zones

Rotor flow and air pressure control area 10 zones

Product thickness 2-6mm

4. Vacuum calibration Device 1 set

Vacuum calibration rack 1set

Air tank 4 sets

Vacuum pump 15kW

Blower 1.5kw

Electrical stick 1 set

Power 0.75kw

Sideway of fixed table 1 set

5. The first hauling off machines of transporting rolls 1 set

(steel frame, deal with by chromium-plating for rolls)

Treatment method outside: Chromium plating

Hauling off speed 1-6m/min

Hauling off motor 7.5kw

Slitting shears 1 set.

Quantity of rollers 5 pieces

Cut edge knife 2 pcs

6. Heat setting oven

1set

Transportation By transporting track

Rack Made by stainless steel

Size : 2400*2000

This production line is a fully automatic production line, using the domestic listed company Xinjie PLC+HIM+ precise temperature control module control system, sinusoidal frequency converter. During normal production, it is only necessary to add raw materials at the head, and then collect the product at the tail. The production process of more than 20 meters long only needs one person to patrol from time to time.

The following machines are by choice , you can buy in your local market

1. Automatic mixer material and color machine 500kg/h

2. Waste edge recycling machines 1000usd

We make the cut the waste edge inline crusher to small pieces can use into the extruder directly , but no more than 30% recycling every time

3. The whole line need to match a swp360 crushe

SWP360 crusher

|

1 |

Moving cutter rotating diameter |

360 |

|

2 |

Motor type and power |

15kw |

|

3 |

Sieve pore diameter |

12mm

|

|

4 |

Moving cutter quantity |

3 |

|

5 |

Fixed cutter quantity |

2 |

|

6 |

Crusher output |

350-400kg/h |

4. 20hp FAN COOLING chiller

| PARAMETER CONFIGURATION MODEL |

SYF-20 |

|

| Refrigerating capacity | Kw 50Hz/60Hz |

59.8 |

|

71.8 |

||

|

Power supply and electrical components (Schneider, France) |

380v 50HZ |

|

| Refrigerant(Eastern Mountain) |

Name |

R22 |

| The control mode |

Internalbalance expansion valve(Hongsen) |

|

| The compressor(Panasonic) |

Type |

Closed vortex type(10HP*2 sets) |

|

Power(Kw) |

18.12 |

|

| The condenser

(Shunyike) |

Type |

High efficiency copper clad aluminum fins +low noise external rotor fan |

|

Fan power and quantity |

0.6Kw*2 sets(Juwei) |

|

|

Cooling air volume(m³/h) |

13600(Model 600) |

|

| The evaporator

(Shunyike) |

Type |

Water tank coil type |

| Frozen water volume(m³/h) |

12.94 |

|

|

15.53 |

||

| Tank capacity(L) |

350(Stainless steel, external insulation) |

|

| Water pump (Taiwan Yuanli) |

Power(Kw) |

1.5 |

|

Lift(m) |

18 |

|

| Flow rate(m³) |

21.6 |

|

| Pipe diameter interface |

DN50 |

|

| Security and protectio |

Compressor overheat protection, overcurrent protection, high and low pressure protection,overtemperature protection, phase sequence/phase protection, exhaust overheat protection. |

|

| Mechanical dimensions(Surface spray) | Long(mm) |

2100 |

| Width(mm) |

1000 |

|

| High(mm) |

1600 |

|

|

Input total power |

KW |

20 |

|

Mechanical weight |

KG |

750 |

Note:1.The refrigerating capacity is based on:freezing water inlet and outlet water temperature 7℃/12℃,cooling inlet and outlet wind temperature 30℃/35℃.

2.Scope of work:frozen water temperature range: 5℃to35℃;Freezing water inlet and outlet temperature difference: 3℃to8℃,The ambient temperature is not higher than 35℃.

Reserves the right to change the above parameters or dimensions without noti

5. Semi-automatic Flatbed Die Cutting Machine

TMZ1620B Semi-Automatic Flatbed Die Cutting Machine

1- Device description

Equipped with high-precision gearbox, fast speed, long life, safe and reliable

The newly designed tooth row system and reinforced chain can effectively improve the stability of paper operation, reduce maintenance and prolong the service life of the machine.

Pneumatic locking system of the die-cutting plate frame, easy to operate, the die-cutting plate frame adopts an integrated structure, which is accurate and durable.

The die-cutting pressure is uniform, the patch is less, and the operation is visual design.

The electric control system adopts PLC control and is equipped with various safety protection devices. When a fault occurs, the sound and light alarm and automatically stop, which truly achieves human-machine safety.

| ITEM | SPECIFICATION |

| Pressure adjustment range | ±1mm |

| Minimum front scrap size | ≥8mm |

| Mechanical top speed | 4000S/H |

| TOTAL POWER | 20.5KW |

| TOTAL WEIGHT | ≈21T |

Three-color printing die-cutting machine

| ITEM | SPECIFICATION |

| machine design speed | 260PCS/MIN |

| Standard plate thickness | 7.2MM |

| Printable Cardboard Thickness | 3-11MM |

| Printing cylinder axial adjustment | ±10MM |