SJSZ-80/156 pvc foam board extrusion machine

| Name of Commodity380V .3P.50HZ

|

Quantity |

|

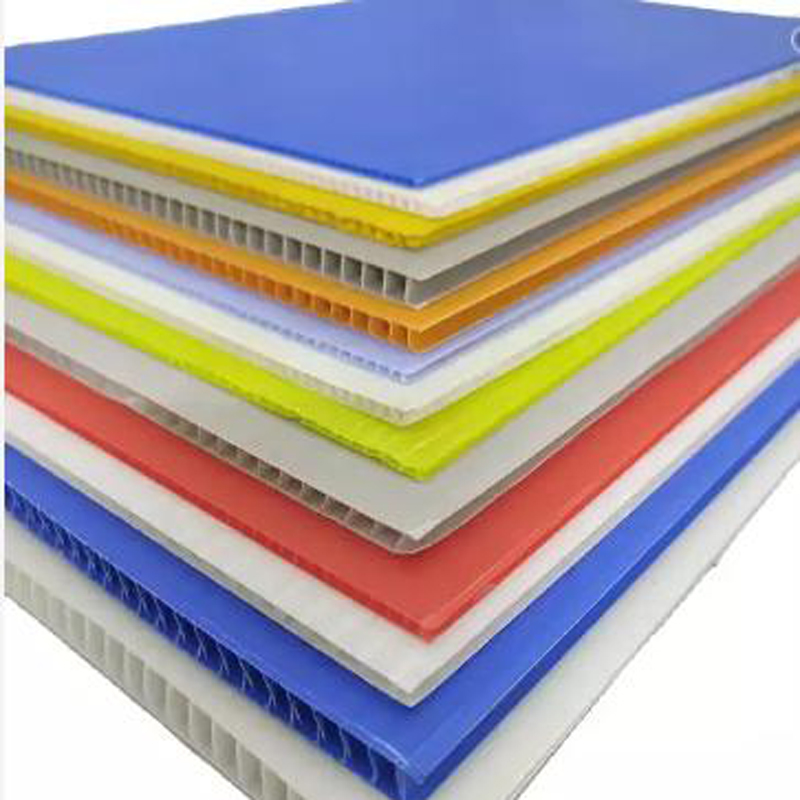

PVC WPC FOAM BOARD PRODUCTION LINE From extruder to stacker 1.automatic feeding system 2.SJSZ80/156 conical twin screw extruder 3. T -die mould ( L2450, W1220,T:3-25mm) 4.cooling calibration platform -4 couples calibrators 5.Mould temperature controller 2 sets 6.cooling support 7.eight pairs rubber rollers traction with Trimming and dust collector 8.cutting machine 9.Automatic discharge and stacker/robert |

1 |

|

20HP chiller |

1 |

|

0.8MPA air compressor |

1 |

|

SWP360 crusher |

1 |

|

SMF630 pulvertizer machine with vibrating system |

1 |

|

SHR500/1000 heating/cooling mixer |

1 |

| No | Name | Type | Quantity | Marks |

| 1.1 | Conical twin screw extruder

With automatic screw feeder |

SJSZ-80/156 | 1set | Equipped with automatic screw feeder |

| 1.2 | Electrical control system | 1set | Delta frequency converter, Siemens contactor | |

| 1.3 | Mould | SJM-1350 | 1set | Oil string device at die port, automatic temperature control |

| 1.4 | Vacuum setting die | SDX-1500 | 1set | 4-stage sizing cooling |

| 1.5 | Hauling off | SQY-1400 | 1set | 8 sets, 16 rolls. |

| 1.6 | Cooling bracket | SJTJ-3000 | 1set | |

| 1.8 | cutting machine | SQG-1220 | 1set | |

| 1.9 | Plate unloading device | SJS-1220 | 1set | |

| 1.10 | Hot and cold mixer | SHR500/1000 | 1set | |

| 1.11 | Crusher | SWP-380 | 1set | |

| 1.12 | Grinder | SMP-630 | 1set | |

2.instruction

| NO | INSTRUCTION | SPECIFICATION |

| 2.1 | RAW MATERIAL | PVC Add auxiliary materials |

| 2.2 | BOARD SIZE | 3-25×1220 |

| 2.3 | Line speed | 0.2-0.8m/min |

| 2.4 | MAX OUTPUT | 350-450kg/h |

| 2.5 | MACHINE SIZE | 26000×2200×2900 L×W×H |

| 2.6 | WEIGHT | 35t |

| 2.7 | Total installed power | 185kw |

| 2.8 | Actual energy consumption power | 125kw |

| 2.9 | Gas consumption | 0.4m3/min |

| 2.10 | pressure | 0.6mpa |

| 2.11 | Water circulation | 0.4 m3/min |

| 2.12 | VOLTAGE | AC380V±10%50HZ |

| 2.13 | WATER | Industrial water, free of impurities, filtered, water pressure: 0.4MPa, water temperature: 15-25 ℃. |

| 2.14 | work environment | 0-40℃ |

| 4.2Electrical control system |

| Frequency converter: ABB /holip /Delta/innovince frequency converterContactor: Siemens contactorThe control panel consists of power indicator, main engine on-off switch and emergency stop button.

Low voltage electrical appliances are Siemens or Schneider products, and the main air switch is Delixi products |

4.5 hauling off

| Rubber roller material: nitrile rubberTraction cots: 8 groups of 16 Cots

Rubber roller hardness: Shore hardness 53-58 degrees Control mode: pneumatic compression, independent control Working width of rubber roller: 1400mm Move back and forth synchronously with the platform The connection mode with the platform is the mother screw and can be adjusted separately |

4.7 cutting machine

Cutting mode: Electric transverse cutting

Thickness of cut plate: 3-25mm

Cutting plate width: 1220 mm

Dust suction device is common to slitting

4.8 board robert /automatic board lifting machine

main parameter configuration of special plate splicer for plate

1、 Overall dimension of equipment: 6500 * 1890 * 2600 (5000) mm;The height of the saw is 1150mm-980 mm, which can be adjusted with the center of the saw, and can be connected with the cutting table by the bracket;

2、 Electrical system:

- Operation mode: PLC + touch screen, brand: Xinjie

2. Low voltage apparatus: Omron, Siemens, Schneider;

3. Alignment mode of plate conveying: stainless steel idler, idler Φ 60mm, number of idler 18, idler drive is cycloid reducer controlled by frequency converter, reducer model is bwy0-9-0.75kw, frequency converter brand: Xinjie;

4、 Lifting system: variable frequency speed regulating brake motor drive, RV Reducer rubber roller guide vertical lifting, motor power 1.0kw, reducer rv63-25, frequency converter brand: Xinjie;

5、 Translation system: servo motor drive RV Reducer, reducer rv63-10, servo motor model: 80st-0.75kw, brand: Xinjie

6、 Plate grabbing method: vacuum suction cup, number of suction cups: 10;

7、 Maximum stacking height: 1400mm;

8、 Maximum grasping weight: 50kg;

9 Maximum operating speed: 50s / time;

10、 Suitable plate size: 1000-3200mmx1220mm;

PVC foam board machine Spare parts :Accessories list:

| NO | Spare parts name | Quantity |

| 1 | Cast alumium heater for 1 zone | 1 pcs |

| 2 | Cooling air fan for barrel | 1 pcs |

| 3 | Spanner for mould | 1 pcs |

| 4 | contactors | 2 pcs |

| 5 | Thermocouples | 5 pcs |

| 6 | heating rods for abrasives | 5 pcs |

| 7 | copper feeler gauge | 1pcs |

| 8 | die adjusting bolts | 5 pcs |

| 9 | Feeding spring for feeding machine | 2 pcs |

| 10 | Pe pipe for feeding machine | 2 pcs |

| 11 | air pipe connectors | 5 pcs |

4.9 SWP380 crusher

| Moving knife 3 piecesFixed knife 2 pieces

Sieve diameter Φ 10mm Large inlet 480 × 320mm Crushing particle size 3-10mm Output 500kg / h Equipped with power of 15kw Wind power 2.2kw Overall weight 2500kg Overall dimension 2 × one point two × 2.4m |

SHR500/1000 hot and cold mixer

| High speed mixer: shr500 / 1000

Material and composition of pot body: 1Cr18Ni9Ti stainless steel, with extremely smooth and hard inner surface, which is characterized by wear resistance, corrosion resistance and not easy to stick. Pot cover material: cast aluminum (the frequency converter controls the motor, with small starting current and more than 30% power saving.) Cooling motor: 15 kw Mixing time: 6-10min Material of discharge body: cast aluminum Unloading mode: pneumatic unloading |

20HP chiller Parameters and configuration table of chiller of Qingdao cuishi

| PARAMETER

CONFIGURATION MODEL |

SYF-20 |

|

| Refrigerating capacity |

Kw 50Hz/60Hz |

59.8 |

| 71.8 | ||

| Power supply and electrical components

(Schneider, France) |

380v 50HZ | |

| Refrigerant

(Eastern Mountain) |

Name | R22 |

| The control mode | Internalbalance expansion valve(Hongsen) | |

| The compressor

(Panasonic) |

Type | Closed vortex type(10HP*2 sets) |

| Power(Kw) | 18.12 | |

|

The condenser (Shunyike) |

Type |

High efficiency copper clad aluminum fins +low noise external rotor fan |

| Fan power and quantity | 0.6Kw*2 sets(Juwei) | |

| Cooling air volume(m³/h) | 13600(Model 600) | |

|

The evaporator (Shunyike) |

Type | Water tank coil type |

|

Frozen water volume(m³/h) |

12.94 | |

| 15.53 | ||

| Tank capacity(L) | 350(Stainless steel, external insulation) | |

|

Water pump (Taiwan Yuanli) |

Power(Kw) | 1.5 |

| Lift(m) | 18 | |

| Flow rate(m³) | 21.6 | |

| Pipe diameter interface | DN50 | |

|

Security and protectio |

Compressor overheat protection, overcurrent protection, high and low pressure protection,overtemperature protection, phase sequence/phase protection, exhaust overheat protection. | |