HDPE double wall corrugated pipe making machine

Maintenance-free cooling system with high water flow

Rapid form jaw change

Multiple mold jaws

Automatic compensation of Formback game

maintenance-free cooling system

Different vacuum zones with variable positioning

Control with touch screen

channel with quick opening function and "Zoom" technology

Weight-reduced form of jaws

Short tool lengths

Higher throughput

corrugated pipe is mainly used for water drainage system. It is a fully computer controlled line. It features high and stable output capacity, and highly automatic operation. For HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin-screw extruder or parallel twin- screw extruder. Forming system consists mould and corrugator.

Mould blocks can be easily changed and they have air or water cooling system. The belling process is on line. High precision cutting can be guaranteed by cutting machine. The production line can also be equipped with SIEMENS PLC system.

| Type Pipe | Diameter(mm) | HDPE Output(kg/h) | MAX Speed(m/min) |

| CS-160 | 50-160 | 300-400 | 4 |

| CS-500 | 200-500 | 600-700 | 3 |

| CS-800 | 200-800 | 1000-1100 | 3 |

| CS-1200 | 600-1200 | 1000-1200 | 1 |

¢200-¢800PE/PPdouble wall corrugated pipe machine

DWC800 high speed water cooling double wall corrugated pipe Equipment composition and configuration description

The production line can produce PE / PP double wall bellows with a maximum outer diameter of 800mm. The installed capacity of the production line is 600kw and the common power is 360KW. Cooling water requirements: ≤ 15 ℃, 0.5mpa, 0.3m3/min. Compressed air requirements: 1.3m3/min, ≥ 0.6MPa

Machine size : 45m×7.0m×4m ( L*W*H)

Brief introduction to equipment configuration and performance

1.SJ-90/36 SINGLE SCREW EXTRUDER for inner layer 1SET

1.1 screw diameter: 75mm;

1.2 length diameter ratio of screw: 36:1;

1.3 screw speed: 9-90r / min;1.4 material of screw and barrel: 38CrMoAlA, nitriding and grinding;

1.5 driving power: 132KW, DC motor, DC speed regulation;

1.6 screw structure: high efficiency barrier screw with special mixing section, which greatly improves the plasticization quality and output;

1.7 barrel structure: the asymmetric slotted barrel design is adopted, and the feed inlet is equipped with a water cooling system with automatic temperature control to double the conveying efficiency of the feed section;

1.8 reduction gearbox: the reduction gearbox adopts vertical structure, and the cooling mode is forced circulating oil cooling, with circulating water cooling system. High torque, low noise, hard tooth surface gear, gear grinding process, plus heavy thrust bearing;

2.SJ-120/33 SINGLE SCREW EXTRUDER ONE SET

2.1 screw diameter: 120mm;

2.2 length diameter ratio of screw: 33:1;

2.5 driving power: 160KW, DC motor, DC speed regulation;

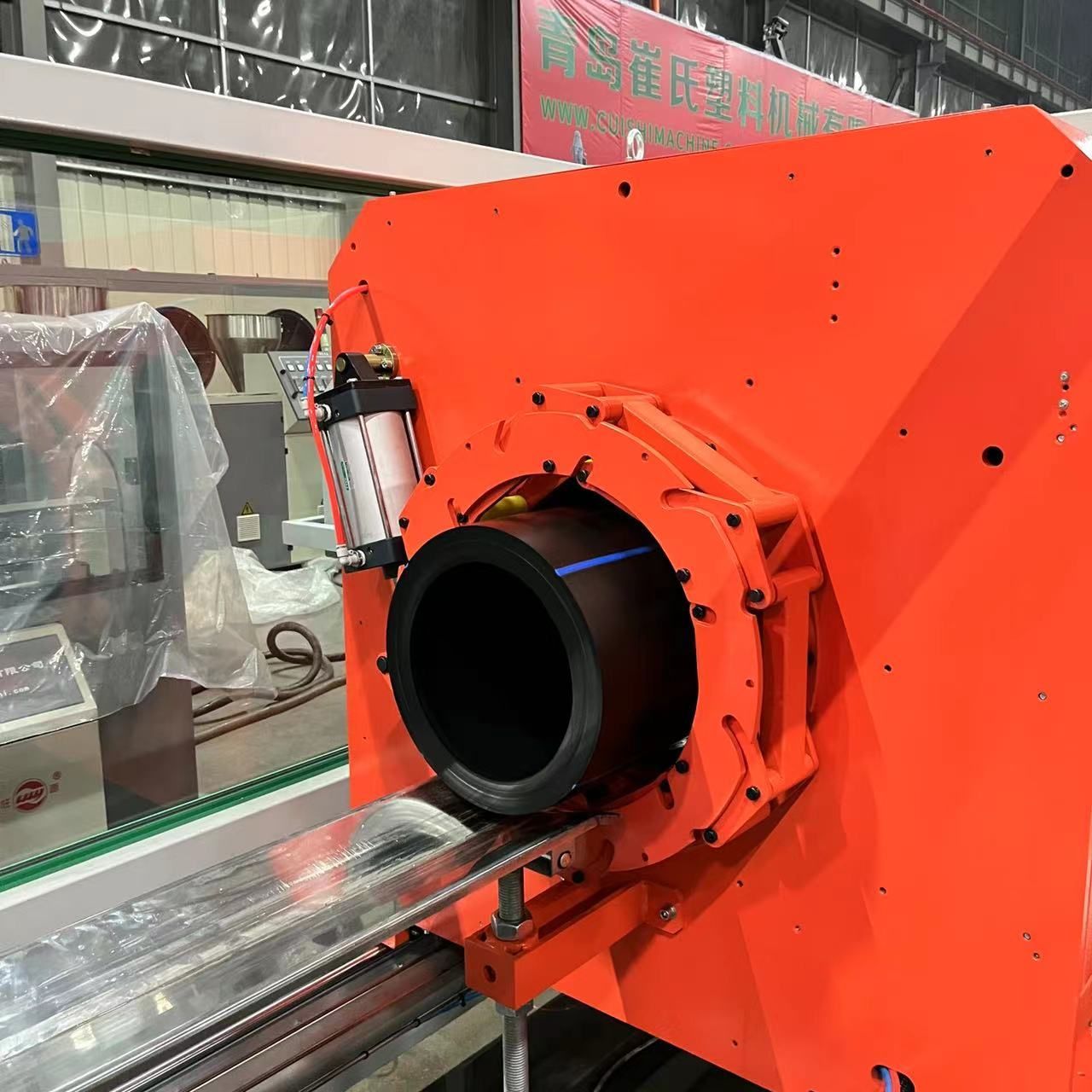

3.DWC-800HIGH SPEED WATER COOLING CORRUGATED FORMING

3.1The corrugated forming machine is arranged in a new horizontal structure. Compared with the vertical structure, the forming machine has higher rigidity, lower center of gravity, more stable operation and easier operation and maintenance;

3.2 the corrugated forming module adopts the innovative water direct cooling structure, which makes the cooling medium circulate inside the module at a higher flow rate and has high cooling efficiency, so as to ensure a higher output of the production line, up to 1800 kg / h (HDPE).

3.3 the innovative structural design of the molding machine makes the left and right frames open and close freely, which brings great convenience for flexible production.

The left and right racks can be opened and closed through simple operation when replacing modules of different specifications or stopping at no-load, which can effectively avoid the cumbersome adjustment work caused by "holding" the die head by the corrugated forming module, so as to improve the convenience of equipment use and maintenance;

3.4 the unique design of the running track of the forming module can make the forming module run in both positive and negative directions;

3.5 the center height of the molding machine is fixed, and there is no need to adjust the frame or platform of the molding machine, so it is easier to use and operate;

3.6 advanced patented module manufacturing technology enables the cooling channel and vacuum channel in the precision cast corrugated module to be cast at one time, with high module strength and long service life, so as to ensure the high-quality and efficient production of pipes;

3.7 the automatic lubrication system is equipped with multiple lubrication points, which can set the lubrication time and frequency for automatic operation;

3.8 the position of the molding machine shall be adjusted electrically and equipped with perfect measuring and feedback devices; Accurately display the adjustment amount of each dimension.

3.9 the forming machine has the exit function in case of emergency;

3.10 the international famous brand PCC control system adopts modular control scheme, which has high compatibility, high control precision and high reliability.

4. CS1000 TYPE WATER COOLING TANK;

4.1 open side cooling water tank, easy to operate and maintain;

4.2 the box body is made of stainless steel;

4.3 automatic control function of water temperature and water level;

4.4 the water tank is equipped with active guiding device to effectively reduce the running resistance of pipes;

4.5 strong blow drying device to completely remove the cooling water on the pipe surface;

5. ONE set 1000 automatic chip free cutting machine

5.1 chip free cutting, hydraulic feed mechanism, high precision, ensuring smooth section;

5.2 auxiliary detection mechanism to ensure that the cutter is accurately located at the cutting position;

5.3automatic and manual switching;

5.4clamping mode: pneumatic clamping;

5.5 PCC control system is controlled and equipped with standard communication interface to facilitate the connection with compatible equipment.

6. CS800 STACKER ONE SET

6.1 the height of the blanking rack adopts electric adjustment, which is convenient to operate;

6.2 provide thoughtful protective devices to ensure the safety of the production site.

7. CORRUGATED PIPE FORMING MOULDS

DN/ID200mm MOULDS BLOCK,module, sizing sleeve die head

DN/ID300mm MOULDS BLOCK,module, sizing sleeve die head

DN/ID400mm MOULDS BLOCK,module, sizing sleeve die head

DN/ID500mm MOULDS BLOCK,module, sizing sleeve die head

CORRUGATED FORMING MOULDS module

7.1.1 the module is made of special aluminum alloy with high thermal conductivity, high hardness and high wear resistance;

7.1.2 the forming module adopts the integral pressure casting process, with more dense texture and higher thermal stability;

7.1.3 the special treatment of the inner surface of the module not only improves the strength and hardness of the module, but also is conducive to the perfect forming of the ripple.

7.1.4 vacuum air passage and water cooling channel with large flow section ensure stable, high-quality and efficient operation of production.

7.2 Spiral channel extrusion die

7.2.1 for the real independent die head design, when changing the specification, just remove several connecting parts of the die head and pull out the heating cable of the die head to complete the replacement of the die head of another specification without redundant adjustment. This not only makes it easier and faster to replace the specification, but also ensures the accuracy of the die and has a long service life by avoiding the frequent disassembly and assembly of the die parts;

7.2.2 the new spiral channel die can effectively reduce the material flow resistance and improve the plasticizing effect by greatly shortening the channel length.

7.3 New aluminum alloy cooling sizing water jacket

Execooc with new structure ™ Aluminum alloy cooling sizing water jacket has excellent wear resistance and excellent cooling effect by re selecting aluminum alloy material and adopting new heat treatment process. It can realize the perfect combination of high heat conductivity light weight and high strength, and effectively overcome the defects of low cooling efficiency of stainless steel cooling water jacket and poor wear resistance of ordinary aluminum alloy cooling water jacket.

Also we have vertical forming machine design