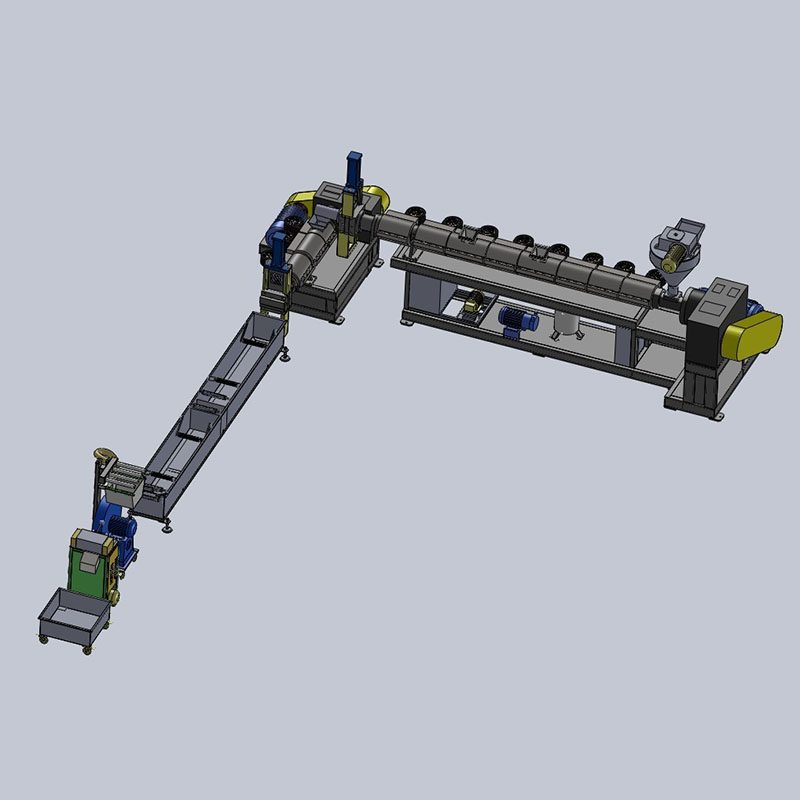

PE PP graulation machine

|

Name of Commodity |

Quantity(set) |

| SJ180/30 pp pe film pelletizer machine | 1 |

| Screw and barrel sj180 /30 as spare parts

Can guarantee 1000tons pp pe film |

1 |

General description:

1、Process material : PE PP soft material

2、Extruder Model: SJ180/30 and SJ180/15

3、Production capacity : 300kg/hour

4、Feeding way : Claw Feeder for film design

5、Pelletizing way : noodles type pelletizing

6、Power supply: 3Phase/380V/50HZ

Part II Product list

A.1 set of claw feeder with 350 gearbox and 7.5kw motor

B.1 set of SJ180/30 Extruding machine with 75kw motor and delta inverter ,with electricity box omron temperature control zones ,Siemens Low voltage electrical appliances with Hard tooth surface reducer

C 1 set of SJ180/15 Extruding machine with 22kw motor and delta inverter ,with electricity box omron temperature control zones ,Siemens Low voltage electrical appliances with Hard tooth surface reducer

D. 1 set of High speed hydraulic screen changing system with non-stop and hydraulic station with 350&350

E 1 set of pelletizer die head

F 1 set of water cooling tank

G 1 set of pelletizer machine

H 1 set of Control cabinet

PP/PE film plastic double stage pelletizing line

(capacity with 300kg/hour in string pelletizing ways)

Detail Technical Parameter of each above machine

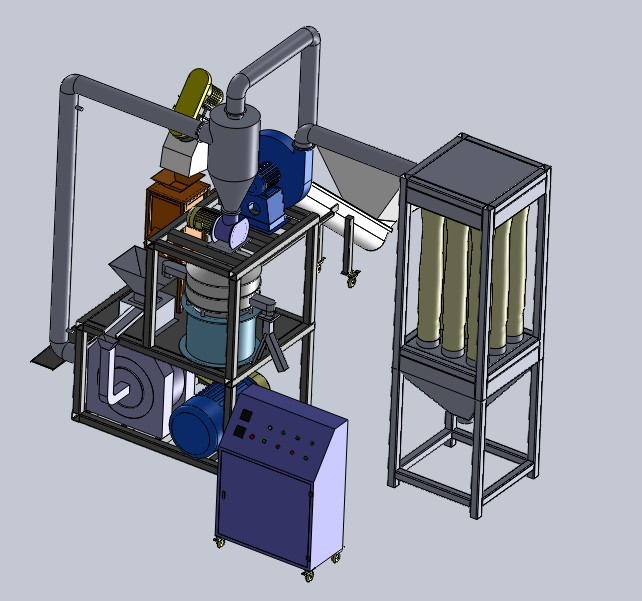

Necessary machine for PE/PP hard plastic pelletizing line

1 set of claw feeder with 350 gearbox and 7.5kw motor

This machine is very important for rigid PE/PP material, it will ensure the PE/PP film go to screw barrel smoothly and equally.

1. Motor: 7.5 KW

2. Material feed way: by claw working way

B.3 SJ180/30 Extruding Machine 1 set

Material of screw and barrel:

①38CrMoA1A, tempering nitrification;

②Tempering rigidity: HB230-250;

③Nitrification rigidity: HV850-950;

④Nitrification depth: 0.5-0.7mm;

Screw barrel temperature controlling: heating zone

Model Gear Box:280type with high torque, low noise, hardened teeth grinding gear box with an external cooling circulatory

8. Way of Lubrication: oiled

9. Temperature controller made in Japan “RKC or delta or omron ”

10. The motor of extruder with high current protect system and low current project system

SJ180/15 Extruding Machine 1 set

Material of screw:

①38CrMoA1A, tempering nitrification;

②Tempering rigidity: HB230-250;

③Nitrification rigidity: HV850-950;

④Nitrification depth: 0.5-0.7mm;

⑤Brittleness: less than level 2

Screw barrel temperature controlling: 3 heating section

Model Gear Box: gearbox with high torque, low noise, hardened teeth grinding gear box with an external cooling circulatory

Way of Lubrication: oiled

8. Temperature controller made in Japan “RKC” or delta or omron ”

10. The machine with pressure sensor system

11. The motor of extruder with high current protect system and low current project system

High speed screen exchanging device and Die-head 1 set

1. No stop hydraulic oil exchanging device

2. The time for changed mesh Net<2 seconds

3. The system working pressure: 16Mpa

Water cooling bath 1set

1. Length of water cooling tank: 4000mm

2. Main material of this water cooling bath: stainless steel 304

Pelletizer 1set

1. The roller with special material for PP Material with enough strong

2 The capacity: 300kg/hour

B.11 Control cabinet for the whole line 1set

Schneider Contactor, RKC/delta/omron temperature controlling instrument, delta Brand frequency converter, Automatic warming system for power overflow and pressure overflow on the extruder. Schneider/Siemens or delixi open circuit protection switch