QINGDAO CUISHI PLASTIC MACHINERY CO.,LTD

Granulator

High quality high output hot plastic pellet/pipe/cubeextruder machine plastic recycling equipment

SJ series single screw extruder plastic machine mainly apply to extrude PP,PE,PET,PVC,ABS,PS,PA ect material.It adopt special gear box,and has features of low noisy ,stable running ,high carrying capacity,long service life .Equipped with different mold and auxiliary equipments, it could produce plastic pipe ,sheet ,board, granules and so on .It has features of simple process,high output ,stable extrusion pressure,and low cost.

| Project: DJ85 single screw pelletizing line | |

| Raw material & formula | PE films |

| Final product | PE granules |

| Output capacity | 120-200kg/h , depends on material’s characteristics. |

| Central height | 1.14m |

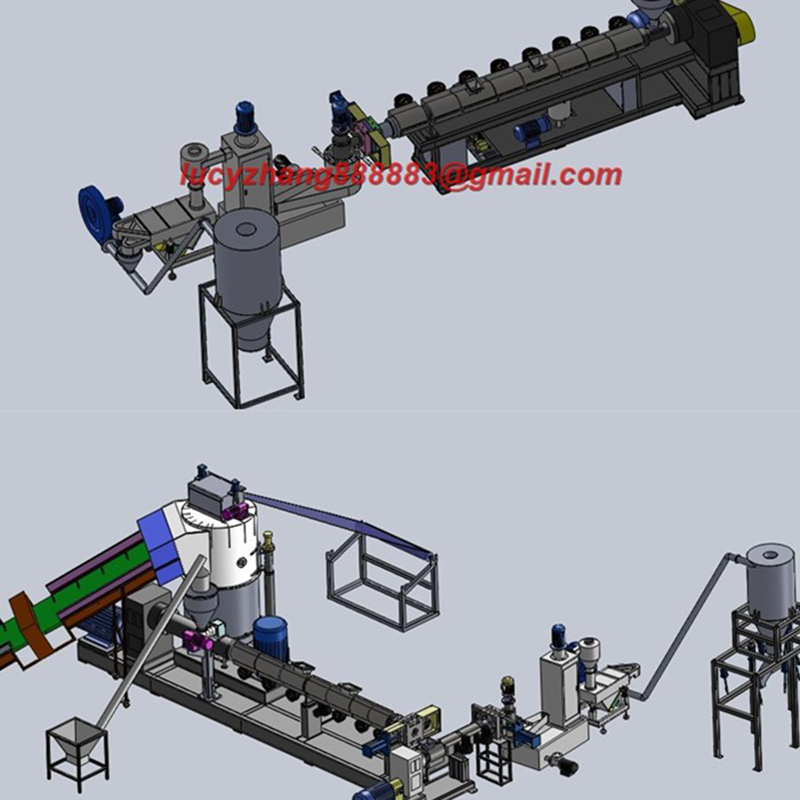

pp pe pelletizing line plastic recycling granulating machine waste plastic granules making machine

Parameters(CS Series Double Stage Compactor-Granulator):

|

Model(double stage) |

CS85-100 |

CS100-120 |

CS130-150 |

CS160-180 |

CS180-200 |

|

Screw Diameter(mm) |

85 |

100 |

130 |

160 |

180 |

|

L/D |

25-42 |

25-42 |

25-33 |

25-33 |

25-33 |

|

Capacity(kg/h) |

150-200 |

300-350 |

500 |

600-700 |

800-1000 |

Application:

PE, PP film, Silk, Flakes (≤0.5mm), Bags, etc.

Note, our CS series compactor granulator can be pull strip cutting method, or water ring cutting method for option

Consist of:

Belt conveyor(metal detector) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub- extruder →

Hydraulic screen changer → Water ring cutting system →Dewatering machine → Air blow system → Storage hopper → control cabinet

- General information

1.1 Floor space

Basic construction, earthwork, wall work should be well finished by Buyer for accepting this pelletizing line.

Buyer should supply crane, forklift or other lifting equipment, mounting materials and tools.

Area: to be designed according to line layout.

1.2 Power supply

Installed power: 106KW (practical power consumption will be approx. 70%)

Power supply:

Supply voltage: 3*380V+N+PE;

Voltage tolerance: +10%/-5%;

Control voltage: 24VDC+220VAC;

Frequency: 50Hz+-2%

Wire/cables:

- Wires/cables from power supply to control cabinet (provide by Buyer).

- All electrical cables from control cabinet to each machine (provide by Buyer).

1.3 Water supply

Consumption: 0.6T/h (water recycles)

Cooling water:

Without dissolved or suspended minerals as phosphor, sulphur, iron, etc.

Inflow temperature T1: max. 15℃

Outflow temperature T2: T2=T1+5℃

Inflow pressure, min: 2.5 bars

Hardness: 5-8ºdH;

Reflux: without pressure

Water hose:

From water supply to every single machine (provided by Buyer).

1.4 Compressed air: 0.6M3/min, 0.4~0.7Mpa

1.5 Operation staff

2-3 People

1.6 Lubrication oil

Acquired in the local market on the recommendation of Seller (provide by Buyer).

- Commercial terms

2. 1Machine list & Price

|

No. |

Device Name |

Model |

Qty(set) |

|

1 |

Belt conveyor |

|

1 |

|

2 |

Compactor |

|

1 |

|

3 |

DJ85/33 single screw extruder |

DJ85/33 |

1 |

|

4 |

Plate type Hydraulic screen changer160 |

|

1 |

|

5 |

Water ring cutting system |

|

1 |

|

6 |

Vibrating screen dewatering machine |

|

1 |

|

7 |

Silo |

|

1 |

|

8 |

Electric cabinet |

|

1 |

2.2 Payment terms

- 40% as deposit by T/T.

- 60% as balance by T/T before delivery and after inspection.

2.3 Delivery time

In 50 working days from the date of receiving deposit.

2.4 Packing

Plastic film.

2.5 Warranty

13 months for mechanical parts from date of bill of lading. Three months guarantee for electric elements if power supply in Buyer’s factory is not stable.

cuishi will charge the Buyer cost price of spare parts after the equipment out of warranty and provide long-term technical guide.

2.6 Installation & Commissioning

- Buyer should get prepared for installation when the equipment arrived, such as power supply, water supply, labors and cranes, etc.

- cuishi will prepare for visa application for the engineers, who will go to Buyer’s factory for commissioning job.

- Buyer should afford round-trip air tickets for the engineers if visa application is approved, and bear expenses generated such as visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

2.7 Validity

- 60 days from quotation date.

3. Technical specification

3.1DJ85 Single screw extruder

5 Water ring cutting system

blade and the die, and the pressure of the knife is automatically adjusted to ensure the uniform cutting force of the knife. Start the system with one key to make the operation of the whole system more convenient; Horizontal die face cutter Power of cutter:2.2kw Power of water pump:2.2kw The cutter is frequency control by inverter |

|

| 6 | Vibrating screen dewatering machine |

Advanced dewatering vibrating screen combined with horizontal centrifugal drying can achieve excellent drying performance and lower energy consumption.cuishi adopts a closed design and is equipped with a soundproof cover, which has low noise and is more user-friendly.

Motor power :0.25kw*2. Parts that contact water: SUS304. Assemble sieves: not welded. Installed and fixed by screws, for convenient replacing new sieves in the future. Springs are surrounded with rubber, to prevent from big amplitude difference caused by spring ageing. Special design to prevent small impurities falling into water pump.

Motor power: 3kw. Rotary speed: 1460rpm Parts that contact water and granules: SUS304. |

|

| 7 | Silo |

| Effective capacity: 700LMaterial of the part in contact with the material Stainless steel | |

| 8 | Electric cabinet |

The control system adopts Siemens control, and is equipped with industrial-grade touch operation screen(optional item)

According to the set logical sequence and material handling process requirements, the linked cuishi system realizes one-key startup, thus avoiding mistakes in the manual startup process.

With the help of a specially customized unit, the cuishi system can realize one-key shutdown of the entire system module to avoid equipment damage caused by incorrect operation during manual shutdown.

cuishi is equipped with an emergency stop function, which is used as an emergency for uncertain risks during the operation of the machine, shutting down the entire system promptly and quickly to avoid secondary accidents and injuries.

Life safety protection device The cuishi system fully takes into account the safety issues of the equipment during operation. Each operating station and rotating part position are equipped with electronic safety switches to ensure the safety of the equipment during operation and avoid potential hazards during the operation of the equipment to cause harm to the customer's operators.

With the help of a precise temperature control system and a targeted optimization design of the plasticizing process section, the cuishi system can ensure the reliability and stability of the final pelleting quality.

With the help of modular control principle and full cognition of the performance of different recycled materials, the cuishi system can ensure that the processed waste material achieves the optimal preheating and compaction state in the compaction chamber, and can avoid the plastic return material from being compacted. Overheating or degradation in the warehouse. Contactor: Schneider Relay: CHNT General switch: CHNT Circuit-breaker: CHNT Note: Customer need to provide the wire from control cabinet to each machine.

|

3.2Spare Parts: FOC

Mechanical part

|

No |

Name |

Unit |

Qty |

|

1 |

Hot cutting blade |

pieces |

2 |

|

2 |

Screw removal tool |

set |

1 |

|

3 |

Asbestos gloves |

pair |

1 |

|

4 |

Input and output shaft oil seal |

set |

1 |

|

5 |

Vacuum O-ring |

pieces |

2 |

Electrical parts

|

No |

Name |

Unit |

Qty |

|

1 |

AC contactor |

pieces |

1 |

|

2 |

Button |

pieces |

2 |

|

3 |

Temperature table |

pieces |

1 |

|

4 |

Thermocouple |

pieces |

2 |

4.Inspection before Delivery

The Seller is responsible for arranging test run before delivery.