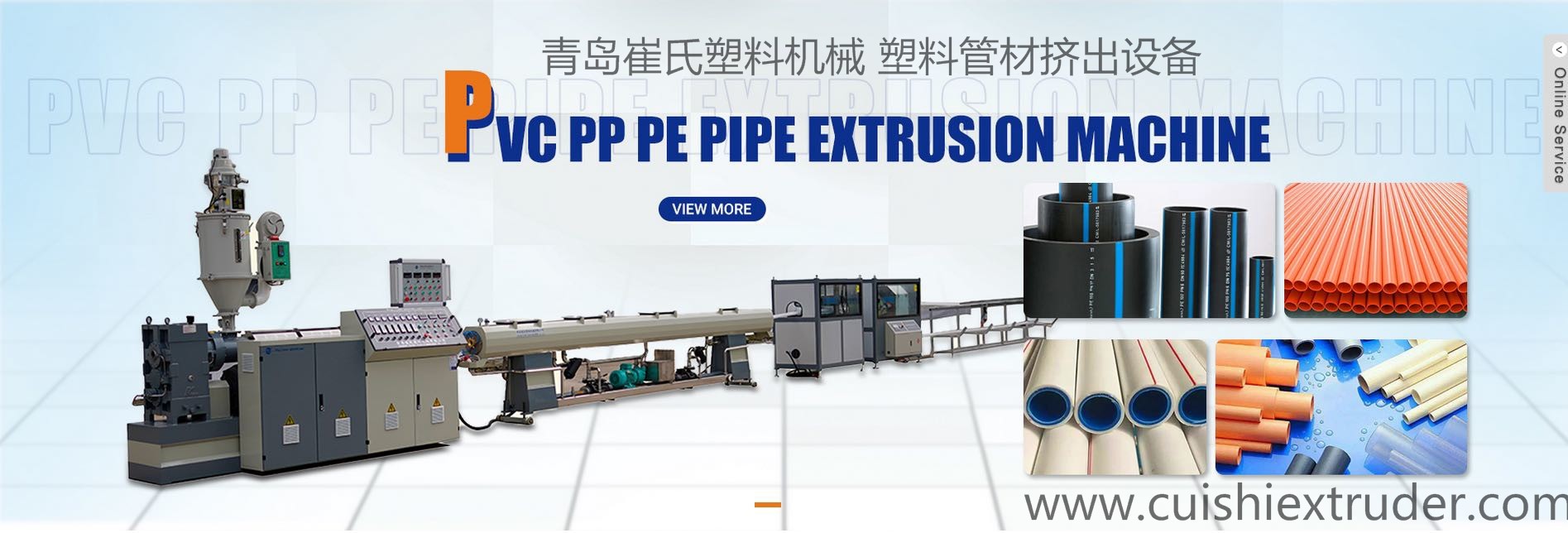

PVC Pipe Extrusion Machine 63-160MM

PVC Pipe Extrusion Machine

Water supply PVC pipe extrusion line plastic conduit pipe extruder machine

The video as following , we test the machine in 2009 years

Our PVC pipe production line adopts advanced technology

We can customize various PVC pipe production lines according to the pipe standards of various countries in the world. Our pipe diameter range is: 16mm-1200mm, from large water supply pipes to small cables We can customize the tube.

Our PVC pipe production lines are spread all over the world and have a large customer base. We will provide all customers with on-site installation, commissioning, training, etc.

Parameters

|

Model |

Pipe range |

Extruder |

Max output |

Max speed |

Total power |

|

PVC-50*2 |

16-50mm |

SJSZ65/132 |

250kg/h |

10 m/min |

85 kw |

|

PVC-63 |

16-63mm |

SJSZ51/105 |

150 kg/h |

10 m/min |

60 kw |

|

PVC-110 |

50-110mm |

SJSZ55/110 |

180 kg/h |

10 m/min |

70 kw |

|

PVC-160 |

63-160mm |

SJSZ65/132 |

300 kg/h |

5 m/min |

90 kw |

|

PVC-250 |

110-250mm |

SJSZ80/156 |

400 kg/h |

3.5 m/min |

120 kw |

|

PVC-315 |

160-315mm |

SJSZ80/156 |

400 kg/h |

3 m/min |

160 kw |

|

PVC-450 |

250-450mm |

SJSZ92/188 |

700 kg/h |

1.5 m/min |

200 kw |

|

PVC-630 |

315-630mm |

SJSZ92/188 |

700 kg/h |

0.9 m/min |

230 kw |

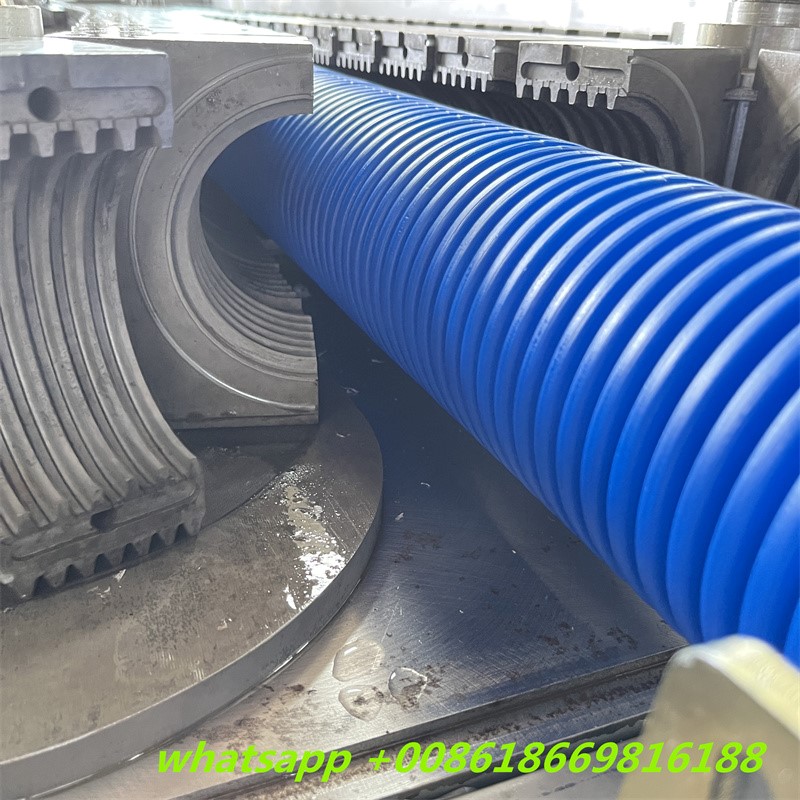

PVC PIPE PLASTIC EXTRUSION MACHINE TECHNOLOGICAL PROCESS

DOUBLE-SCREW EXTRUDER---DIE HEAD & MOULD & SIZING SET---VACUUM WATER COOLING TANK--- TRACTION MACHINE-----CUTTING MACHINE-----AUTOMATIC UNLOADING RACK

The unit consists of conical twin screw extruder, PVC pipe extrusion mould, vacuum calibration tank, haul-off machine, planetary saw cutting machine, tripping table, belling machine.

And the line can be equipped with comptroller thickening instrument, computer ink-jet printer, crusher, shredder, pulverizer, water chiller, air compressor etc.

16-110mm PVC pipe production line

Detail Technical Parameters of Each Above machines

1. screw loader feeder

| 1 | Screw load pipe diameter | mm | Φ110 |

|

|

||

| 2 | Screw pipe length | mm | 4200 |

| 3 | Screw loader motor | Kw | 2.2 |

| 4 | Screw loader size | mm | 900*1100*960 |

2. Conical twin screw Extruder SJSZ80/156

Mould for PVC pipe ONE SET

| Item | Description | Remarks |

| special designed pre-cooling parts can make sure smooth and shiny pipe surface

Mould 1.Material of mold body is Steel 45# ,harden treated and polished. 2.Material of inner mould parts is 40Cr.

|

||

| 1 | OD |

63MM,75MM,110MM,160MM |

| 2 | Material of the mould body | Steel 45#(superior mold steel) harden treated |

| 3 | Material of the inner parts in mould | 40Cr(superior mold steel) harden treated |

| 4 | Material of calibrator | Stannum Bronze |

| 5 | Pressure rating(or pipe wall thickness) | According to the file you sent |

4,Vacuum Calibration and cooling Tank

| Item | Description | CS160 |

| Function:

calibrate the outer diameter and cool ﹡ automatic water level control and water temperature intelligent display ﹡ electric cabinet with water-proof protection ﹡ forceful concentrated spraying water cooling with good cooling effect ﹡ vacuum pump and water pump adopts good product with durable steady working quality. ﹡ Perfect pipeline design with impurity filter device can keep nozzle unblock |

||

| 1 | Length | 6000mm |

| 2 | Material of tank | stainless steel304 |

| 3 | Cooling Type | Water Spray-pouring cooling |

| 4 | Vacuum Pump power | 4kw * 1 sets vacuum pump

And water pump 3kw |

| 5 | Water Pump power | |

| 6 | Left and right position adjustment | Manual adjusting |

51 set of Hauling off Machine

| NO | Description | Unit | Remark | ||||

| ﹡Pneumatic clamping, variable frequency speed adjusting

﹡adopt famous brand cylinder Due to diameter, it can be designing of double, three, four, six, eight caterpillars |

|||||||

| Function: haul off PE pipe stably and synchronal with extruder speed | |||||||

| 1 | Available pedrail length | mm | 1500 | ||||

| 2 | Clamping Mode | Pneumatically | |||||

| 3 | Speed Adjusting Mode | Frequency Conversion | |||||

| 4 | Hauling Motor Power | KW | 2.2kw | ||||

| 5 | Hauling Speed | m/min | 0.5~20 | ||||

| 6 | PIPE DIAMETER | 16-160MM | |||||

| automatic dust free cutting, with meter counting function

﹡Saw blade adopts carbide blade Alert Alarm and counting set of free dust cutter 10 , stacker Due to diameter, it can be designing of saw cutter or planetary cutter |

|||||||

| Function: cut HDPE pipe in fixed length

|

|||||||

| 1 | Cutter type | Automatic meter counting cutter | |||||

| 2 | Suitable cutting pipe diameter | 16-160mm | |||||

| 3 | Cutting speed | Synchronization, automatic cut in fixed length | |||||

| 4 | Motor power | KW | 2.2 | ||||

| 5 | Material of Cutting Saw | Alloy steel | |||||

| 6 | Clamping Mode | Pneumatically Drive | |||||

10 , stacker

| 1 | Stacker | 6m |

|

||

Laser printer one set