Post Tensioning Galvanized Pipe Making Machine Duct Manufacturing Machines

Metal Pipe Corrugated Duct Making Machine

Post Tension Duct Forming Machine

Prestressed Post tensioning spiral concrete construction Galvanized Sheet Spiral Ducting Corrugated

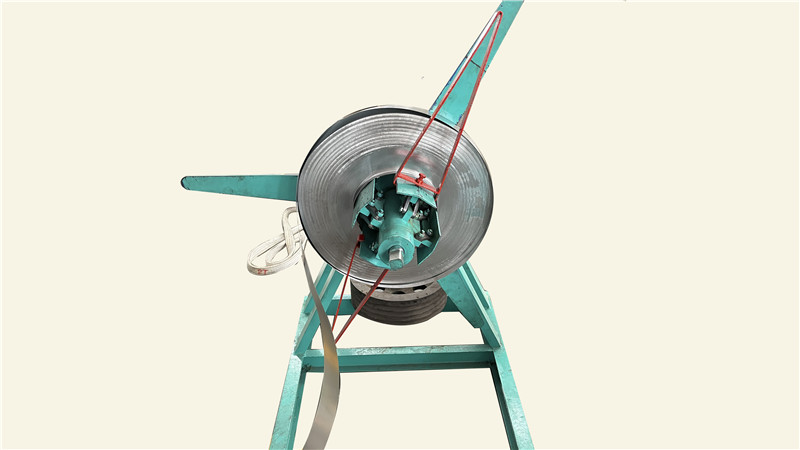

corrugated pipe machine a kind of equipment for producing pre-stressed concrete reserved tunnel metal bellows makes the galvanized steel strip coil into four wave shape then undercuts and swages to apply the bellows, Which With high efficiency and Small volume, Easy operation and maintenance, convenient and speed adjustable. It is suitable for centralized use at construction sites and factories.

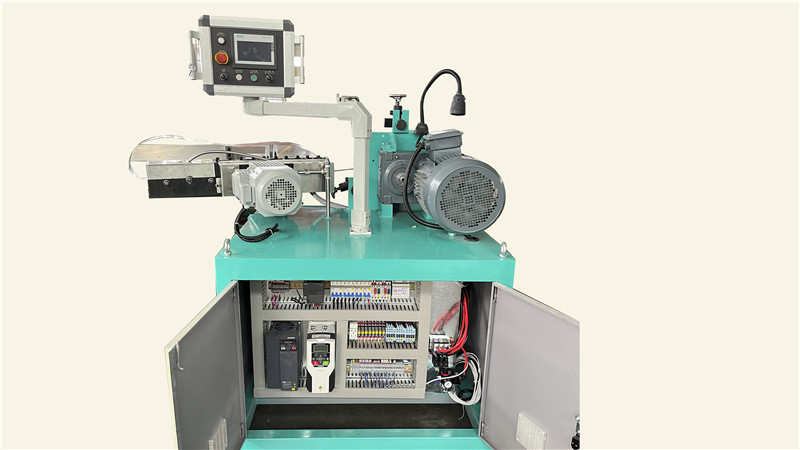

| Model | CUISHI-110 |

| Width of strip | 78mm fixed |

| Thickness of steel band | 0.2-0.6mm |

| Pipe diameter | Φ40-φ130 |

| Pipe Joint mode |

Four l-lock |

| Weight | 1000Kg |

| Pipe rolling speed | 20m/min(maximum) |

| Power | 15KW |

| Cutting motor: Model | Automatic |

| Power | 3KW |

The metal corrugated pipe machine is a kind of equipment for producing pre-stressed concrete reserved tunnel metal bellows makes the galvanized steel strip coil into double wave shape then undercuts and swages to apply the bellows, Which With high efficiency and Small volume, Easy operation and maintenance, convenient and speed adjustable. It is suitable for centralized use at construction sites and factories.

1.Easy to learn, easy to understand.

Three to five days to learn; factory a professional system technician.

2.Save material.

(0.25mm thickness ×78mm width) of the steel, it could produce more duct; other models machine ,four corrugation save more steel , about save 12% material than two corrugation

And the steel corrugated pipe has more light weight

3.Fast, with stepless speed motor.

Main motor 15kw

Cutting machine power: N = 2.2kw

(All-round worker: Dia 70: 10000 m / 8h )

4.Durable

Make 1000,000meters needn’t extensive repair for mould

|

Name of Commodity |

Quantity |

UNIT PIECE(USD) |

FOB qingdao USD |

| Prestressed metal bellows equipment |

1 set |

15000 |

15000 |

Configuration list of prestressed metal bellows production equipment

Production technical conditions

1. Adaptive power supply: 380v/3p/50Hz

2. Adaptive materials: Galvanized steel strip( steel strip width 78mm, thickness 0.25-0.6mm)

3. Extrusion volume: 1000m / h (max.)

4. Product specification: Prestressed metal bellows

5. Production line speed: 1-20m/min

6. Center height of extruder: 1150mm

7. Operation direction: Right to left

Installed capacity: 18.7Kw

5.Quality

In line with JG / T225-2007 standard(Corrugated Metal Ducts for Prestressed Concrete) “Industrial standards of People's Republic of China”

A.Radial rigidity≤ 0.2;

B.Tensile load≥4500N;

C.Concentrated load resistance 800N deformation is not greater than 0.2d.

6.Inner diameter of pipe:

(A type) Dia 35mm - Dia 135mm

(B type) Dia 35mm - Dia 300mm

7.Steel strip thickness: 0.22 ~ 0.6mm

8.weight: 1000kg

9.Machine size ( L*W*H) = 2.5m *2m *2m