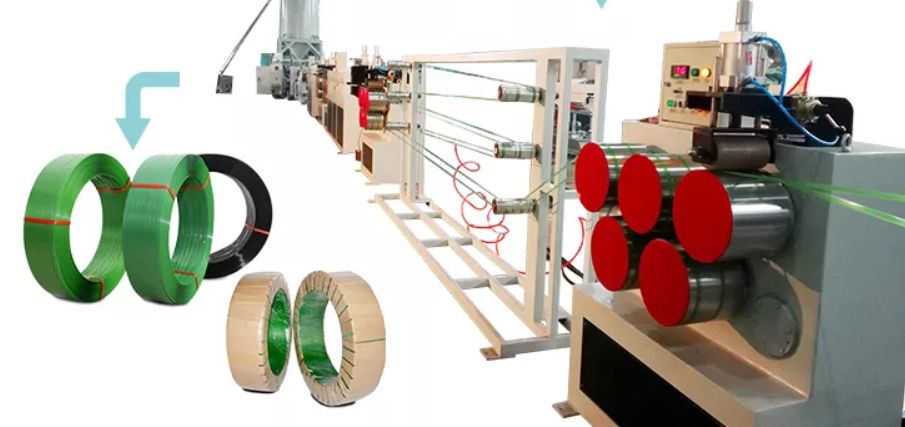

PET packaging belt production line

I. Basic parameters:

Processing: 100% PET bottle or new (viscosity 0.75 or more)

Technical parameters for raw materials

| Raw material A: 100% | |

| cycle stock | PET bottle chip fragments |

| Raw material shape | Maximum diameter of 8-10mm |

| thickness | >400micron |

| IV | 0.75-0.9dl/g |

| density | 0.35-0.40kg/dm3 |

| The original water | <1% |

Specification width of 9-19mm (our routine)

Package belt thickness of 0.6-1.2mm

break strength <40-45kg/mm ²

extensibility 10-15%

Squeeze out a few two

Extrusion Volume, Max. 180-220Kg/h

Line speed is 120m / min 2

Applicable power supply is AC 380v / 3HP / 60Hz

installed capacity 152kw (working capacity of about 95kW)

Operators, 1-2 people

Overall size: 40m×2m×3.5m

Two, production line group

| order number | name | model | quantity | remarks |

| 1 | Dry the precrystallization system | 1500L | 2 set | |

| 2 | dehumidifier | 1 set | ||

| 3 | single screw extruder | SJ-90/30 | 1 set | |

| 4 | Column change net | 1 set | ||

| 5 | controlled volume pump | 1 set | ||

| 6 | Flow der head (mold) | 1 set | ||

| 7 | bosh | 1 set | ||

| 8 | First five-roll preheater | 1 set | ||

| 9 | Tensile oven (heating box) | 1 set | ||

| 10 | The first stretch machine | 1 set | ||

| 11 | The second stretch machine | 1 set | ||

| 12 | coining mill | 1 set | ||

| 13 | Tighten the heat setting device | 1 set | ||

| 14 | bosh | 1 set | ||

| 15 | Three-roller tractor | 1 set | ||

| 16 | PLCDual-station winder | 2set | ||

| 17 | electric control system | 1 set |

| 1. Made of 202 # stainless steel, with double barrel body design, 1.5MM² inner layer, 1.5MM² outer layer, and a visual window is installed on the barrel body | |||||

| 2. The dryer capacity is 1200KG, the electric thermal power is 4KW, and the mixing motor power is 5.5KW | |||||

| 3. Use the 3HP deceleration motor to rotate |

|

|

|

||

| 4. Equipped with scaffolding, which is made of 3.0T cold plate |

|

|

|||

| 5. The bottom is equipped with a straight-pull material drop port |

|

|

|

||

| 6. Clean the door design and clean the door |

|

|

|||

| 7. The middle mixing rod adopts ¢ 50 stainless steel seamless pipe, and the mixing blade is made of 3.0 reinforced stainless steel plate. | |||||

| 8. Adopt Huawei heat circulation fan as the hot air transmission source |

|

|

|||

| 9. Install 50~300℃ overtemperature protection |

|

|

|

||

| 10. Use electronic panel control, automatic and regular operation, a day within 24 small adjustable start |

|

||||

| 11. There is a break-even and overheating indication, and the temperature deviation of PID temperature control mode is small |

|

|

|||

| 12. Blower-blowing type design to make the temperature more uniform |

|

|

|

||

13. System operating conditions

| 1 | Power for electricity | AC 415V±10% 60HZ 3P+N |

| 2 | cooling water | ~20℃ 0.2~0.3Mpa 300L/min |

| 3 | Dry raw materials | Water content was 0.45% before PET drying |

14. Production capacity

| 1 | drying power | PET 500Kg / h (accumulation density: 0.5T / m³) |

| 2 | delivery capacity | PET≥500Kg/h |

| 3 | Transfer distance | L≥6m H≥6m |

| 4 | Installation workshop | Indoor 0℃ ~30℃, relative humidity 20%~70% |

| 5 | Equipment color | KH Standard color or user requirements |

1) dehumidifier

|

|

|||

| The power consumption of regenerative windmill is 2.2KW, and the power consumption is 20KW | ||||

| 3. Automatic microcomputer digital controller can obtain stable dew point dry air. | ||||

| 4. Adopt the LED interface display system and the automatic fault display function. |

|

|||

| 5. Sweden has imported dehumidifying wheels with a long service life. |

|

|||

| 6. Suitable for ordinary and optical antipyretic and drying. |

|

|

||

| 7. Motor reverse phase and overload protection. |

|

|

||

| 8. It has overtemperature alarm and fault display function, simple internal structure, fault bottom, convenient maintenance. | ||||

| 9. Use the high pressure fan as the circulation and regenerative wind pressure source to ensure the normal operation of the machine. | ||||

This machine is main used to make pet strap ,pet packing strap .

Adopt the plc control the whole line do the auotmatic production

it use the melting pump and pressure sensor ensure the production stable and strap quality control

The raw material you can use is 100% recycled pet flakes from the waste pet bottles,or virgin material or mixed with each other.

Advantage:

1.Use 100% Recycled PET Flakes to reduce the cost

2.Good dehumidifer drying system(Crystallization system optional ) to ensure the material equal dryer to produce high quality strapping

3.Special design hot forming tensile tank to make good forming ,equal width,straight strap

3) cylindrical net change

Heating area area 2

Heating power:, 2KW 2

Material: PET (bottle sheet) (0.7-0.95)

Filter level: 40 / 80 / 120 mesh (425 / 180 / 125um)

4) Measurement pump

Pump body: internal flow channel of nitride tool steel for mirror treatment

Gear: tooth shape straight teeth or oblique teeth tool steel / special alloy for mirror treatment

Shaft sleeve: tool steel / special alloy

Heating method: Heating of circulating water

Cooling mode: the shaft-end cooling system

Axis shape: biaxial drive, cooling with water

Axial seal: spiral discharge

5) Flow extension machine head (mold)

Made of high-quality mold steel, compact structure, reasonable connection and convenient replacement. Replace the mold mouth to produce 9-19mm specification products.

Flow channel surface plating hard chromium and polishing treatment, thickness 0.03-0.05mm, hardness HRC50-60, polishing accuracy 0.02-0.06um.

The outer surface is chrome plated layer 0.02-0.03mm for easy maintenance and rust prevention.

Number of strips: 2 strips

Stainless steel heating rod internal heating, stainless steel heating ring connection neck heating, power 4kW.

Pressure-sensing reading area of 0-350bar

7) Cooling sink

Low adjustment: manual lifting

Temperature control area (quantity) area 1

Stainless steel heating pipe and stainless steel shield

All parts in contact with water are made of 304 stainless steel

8) The first and three-roller tractor

For stretching before preheating, composed of motor, reducer, three traction steel rollers and transmission gear. Frequency conversion speed regulation, oblique gear transmission is low noise, smooth transmission.

Motor transmission mode: turbine turborod

The clamp roller is 120mm in diameter, with high temperature rubber coating and mechanical clamping.

9) Tensile oven (heating box)

The heating box mainly completes the tensile heating of the PET casting after molding. The heating speed is fast, which can quickly complete the orientation stretching of the PET band.

Heating power is 10.5kW

Temperature difference (℃), + / -1℃

Temperature control zone 1

10) The first stretching machine

For stretching after heating, composed of motor, reducer, five traction steel rollers and transmission gears. Frequency conversion speed regulation, oblique gear transmission is low noise, smooth transmission.

Roller table is fully coated with hard chromium sandblasting treatment

The clamp roller is 120mm in diameter, with high temperature rubber coating and mechanical clamping.

11) The second stretching machine

For stretching after heating, composed of motor, reducer, five traction steel rollers and transmission gears. Frequency conversion speed regulation oblique gear transmission is low noise, smooth transmission.

Roller table is fully coated with hard chromium sandblasting treatment

The AC frequency conversion drive motor power is 11kw

The clamp roller is 120mm in diameter, with high temperature rubber coating and mechanical clamping.

12) Flower press

The press presses the surface of the PET packing belt to improve the lateral strength and surface friction of the belt.

It consists of the following components

-Welded steel body construction

-Carburized steel upper and lower roll

-Roller diameter of 150mm, roller surface treatment of HRC55-60.

-Effective width, 220mm

-Frequency conversion AC motor is 5.5KW

-Line speed: 140m / min

Using hydraulic drive, the embossing is smoother and easier to operate

13) Tighten the thermal setting device

Tightening hot setting is used for the rapid hot setting of PET band after tensile, to prevent the internal stress elimination of PET band after tensile orientation and stabilize the size of PET band.

13) Cooling water tank

The cooling tank is used to control the complete cooling and crystallinity of the packing belt and ensure the size stability of the packing belt. Made of stainless steel.

Cooling medium: water

The sink length is 4,000mm

15) Three-roller tractor

For the traction and stretching of the PET belt after tightening the heat setting and cooling setting. Made of motor, reducer, traction roller and transmission gear, the whole casting transmission box, no deformation, low gear transmission noise, smooth transmission.

16) PLCDual plex remachine

For product volumes, the center automatically arranges the volumes. It consists of receiving coil, coil core, drive device, wiring device, rack, electrical control, etc.

The PET is packed with a standard paper cartridge

Composition of rolling receiver:

Nacelle-type structure

The rated diameter of the paper tube is 406mm

17) Electrical control system

frequency transformer: ABB

Temperature control meter: Omron

Contactors: Siemens

Touch screen: Siemens

Main motor: Siemens