Bottom price Hdpe Dwc Pipe Machine - prestressed corrugated pipe machine pp+caco3 – Cuishi

Bottom price Hdpe Dwc Pipe Machine - prestressed corrugated pipe machine pp+caco3 – Cuishi Detail:

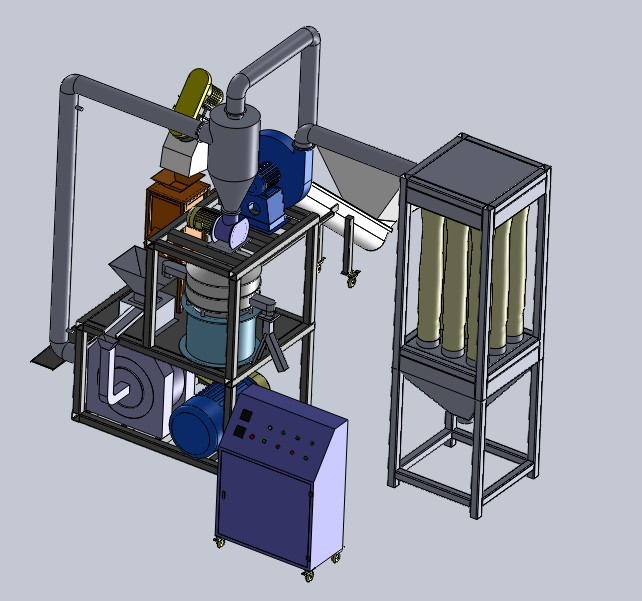

Prestressed bellows production line

Prestressed pipe equipment

Modular prestressed bellows device

PVCPEPP single-wall, double-wall bellows, prestressed bellows production line

The production of PVCPEPP single-wall and double-wall bellows production lines mainly produce PVC, PP, PE as raw materials for the size of the caliber single and double wall bellows. Smooth inside and out, uniformly corrugated products are molded by the corresponding mold at once.

The bellows production line is equipped with a single screw extruder extrusion PP and PE or a twin screw extruder extruding PVC, a bellows forming machine, a tube tire mold, an air cooling device, a meter meter, and a winding machine, which can be continuously extruded into a variety of specifications of large and small diameter bellows.

The structure design of special screw and mold is reasonable, the replacement of the mold is convenient and reliable, which solves the problem of easy wear of the screw barrel and the difficulty of material forming, the production line is fast, the operation is stable, and the control is simple and easy to operate.

The bellows forming machine is a closed structure, the molding module moves back and forth in an integrally closed forming tunnel, the molding tunnel is designed for the sandwich, and the forced cooling module is uniformly cooled by cooling water, and the molding module has no connection with each other, shortening the time to change specifications, high production speed, and fast cooling.

High-speed tapered twin screw extruder host equipment pipe making machine, using Huichuan inverter and servo motor, power saving 30% bearing using original imports, high transmission life, can withstand the maximum extrusion pressure, screw using oil cooling system, barrel using Taiwan fan cooling, the system using computer control, according to different customer needs, the configuration of the most reasonable structure of the screw, to achieve the best plasticization state and logistics quality, more efficient output, built-in vacuum pump system, electrical system to the greatest extent using imported originals, and It has a number of fault alarm functions.

Vacuum forming machine using advanced technology, independent research and development design, reasonable structure, practicality, durable, each part is with more than ten years of experience in the master carefully built, the template integrated molding, mold after special treatment, strong cooling corrugated molding system, can ensure the high speed of continuous production, advanced lubrication system to make the molding module wear the lowest degree, enhance the service life and precision of the mold to maintain, online flaring function

Screw、barrel design and manufacturing absorb European advanced technology

﹡Screw and barrel material:38CrMoAlA,nitriding treated

﹡adopt original famous electric components with high steady running quality . Eg:

RKC or Omron temperature controller, AC speed regulator、low-voltage breaker adopts Schneider or Siemens

﹡Gearbox adopt high torque, low noise, hard gear tooth face gear box

﹡Self protective system:

current of motor overload automatic stop protection

screw displacement automatic stop protection

Lubrication oil starvation automatic alarm device

| ﹡Screw、barrel design and manufacturing absorb European advanced technology

﹡Screw and barrel material:38CrMoAlA,nitriding treated ﹡adopt original famous electric components with high steady running quality . Eg: RKC or Omron temperature controller, AC speed regulator、low-voltage breaker adopts Schneider or Siemens ﹡Gearbox adopt high torque, low noise, hard gear tooth face gear box ﹡Self protective system: current of motor overload automatic stop protection screw displacement automatic stop protection Lubrication oil starvation automatic alarm device Screw and barrel |

|||

| 1 | Screw Diameter | mm | ¢65/132 |

| 2 | Screw length | mm | 1430 |

| 3 | Material of Screw and Barrel | / | 38CrMoAlA Nitrogen Treatment |

| 4 | Depth of nitration case | mm | 0.4-0.7mm |

| 5 | Hardness of nitration | HV | 》940HV |

| 6 | Roughness of the surface | Ra | 0.4un |

| 7 | Hardness of double alloys | HRC | 55-62 |

| 8 | Depth of double alloys | mm | 》2 |

| 9 | Heating Power | KW | 24 |

| 10 | Barrel Heating | / | Casting Aluminum Heater |

| 11 | Barrel Cooling | / | Low noise blower cooling |

| Transmission case | |||

| 1 | Applicable standard | / | JB/T9050.1-1999 |

| 2 | Material of gear and shaft | / | Adopt high strength alloy, carburizing and quenching, grinding |

| 3 | Gear precision and hardness | / | 6grade, HRC 54-62 |

| 4 | Oil sealing | All sealing adopt good products | |

| 5 | Screw Safeguard | / | Automatic screw displacement alarm |

| Dosing feeding device | |||

| 1 | Type | / | Screw dosing feeder |

| 2 | Feeding motor power | KW | 1.5 |

| 3 | Feeding speed regulator | / | Holip Brand inverter |

| Motor and electric system | |||

| 1 | Motor Power | KW | 37(AC motor) |

| 2 | Speed adjusting mode | / | Holip or other famous Frequency conversion adjusting |

| 3 | Max Output Capacity | Kg/h | 50-300kg |

| 4 | Vacuum exhaust system | / | by vacuum pump |

| 5 | Temperature Controller | / | RKC, Japan |

| 6 | AC contactor | / | Siemens |

| 7 | Voltage | / | According to requirement |

| 8 | Extruder axis height | mm | 1000 |

Corrugated modules made of special alloy materials have extremely high hardness and wear resistance, and have good heat dissipation effects

The advanced module quick change system can greatly reduce the time to replace the module, and the molding module with different waveforms can be designed according to the different requirements of the user

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Bottom price Hdpe Dwc Pipe Machine - prestressed corrugated pipe machine pp+caco3 – Cuishi , The product will supply to all over the world, such as: Macedonia, Oslo, Anguilla, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.