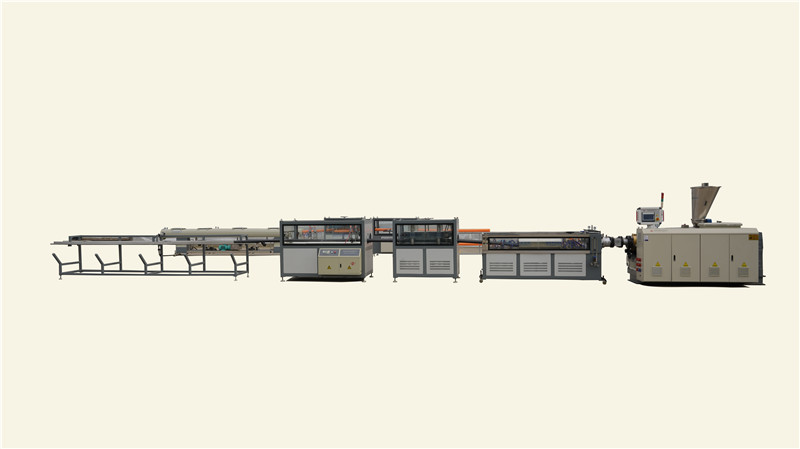

Best quality Plastic Pulverizing Machine - PET PP strap packing tape extrusion line – Cuishi

Best quality Plastic Pulverizing Machine - PET PP strap packing tape extrusion line – Cuishi Detail:

Wechat/whatsapp :0086 18669816188

Qingdao cuishi machine co.,ltd

FOB QINGDAO USD90000 , OUTPUT 2TON/24HOURS

Technical Specification

Ⅰ. Equipment List

| No. | Names | Quantity |

| 1 | Dehumidifying and Crystallizing Equipment | 1set |

| 2 | SJ-75/33 Single Screw Extruder | 1set |

| 3 | Non-stop Screen Changer | 1set |

| 4 | Mold | 1set |

| 5 | Water Tank Cooling System | 1set |

| 6 | Drying Device | 1set |

| 7 | The Five Rollers Haul-off | 1set |

| 8 | Heating Oven | 1set |

| 9 | The First Haul-off | 1set |

| 10 | The Second Haul-off | 1set |

| 11 | Embossing Machine | 1set |

| 12 | Hot Shaping Machine with Cooling Tank | 1set |

| 13 | Drying Device | 1set |

| 14 | The Three Rollers Haul-off | 1set |

| 15 | Winder | 2sets |

| 16 | Control system | 1set |

Introduction

1. Installation power: 120kw, real electricity consumption 70% of it.

2. Material: PET flakes

3. Machine Dimension: 28*4*3.5m

4. Product Dimension: Thickness: 0.5-1.2mm Width: 9-19mm

5. Manpower: 2 persons required to operate whole plant

ⅠProduction Process

Material→ Dehumidifying and Crystallizing → Extruding → Mold → Cooling → Haul-off →Oven Heating →Pre-heating → Drawing and Stretching→ Embossing →Hot Forming → Drawing → Winding

ⅡTechnical Data

1Dehumidifying and Crystallizing Equipment

Other companies use a vertical system, and it is only for drying, and our system is for dehumidifying and crystallizing. Because the molecular chain of the PET bottle flakes is broken, and our system can link them and plays a physical viscous role which can greatly improve the tensile strength of the final products

Main technical parameters:

Capacity: 600 kg;

Quantity: 2pieces

Blender motor power: 4kw

Fan motor power: 2.2kw

Heating power: 18kw (can switch)

Automatic feeding machine 1 piece Motor power: 2.2kw

2SJ-75/33 Single Screw Extruder

This machine is equipped with specialized reducer, and the gear and axial parts adopt high strength alloy steel and are treated by the carburization, quenching, gear grinding and other workmanship, and are matched with super thrust bearing which has the traits of high bearing capacity, stable transmission, and excellent efficiency etc. The material of screw and barrel is 38CrMoAlA, nitriding treatment, lower noise, corrosion resistance, wear resistance. Barrel is cooled by wind, heated by cast aluminum heating circle. The whole machine is equipped with automatic temperature controlling switchboard, digital display intelligent temperature controller.

Main technical parameters:

Screw

Diameter: 75mm

The length-diameter ratio: L/D33:1

Material: 38 CrMoALA

Nitride depth: 0.5-0.7mm

Barrel

Material: 38 CrMoALA

Nitride depth: 0.5-0.7mm

Hardness (HV): ≥940

Heating control areas: four areas

Heating power: 24KW

Cooling system: air cooling

Gearbox

The material: QT200

Type: Inclined gear

Gear material: 20 CrMnTi

Gear surface heat treatment: Gear surface quenching

Thrust bearing: NSK

Lubrication system: pressure lubrication system

Cooling system: external independent cooling cycle system

Main motor

Transmission way: Inverter control

Transmission power: 22kw

Output

Max output 80kg/h

3Non-stop Screen Changer

Main technical parameters:

Max. Working Pressure: 16Mpa

Filter Area: 2*0.5m2

Filter Precision: 120mesh

Heating power: 8.4kw

Double passages

4Mold

It is made of excellent die steel, having the quality of extruding fast and equably, with low pressure.

High precision, long life.

The orifice is adjustable.

One strap design

5Water Tank Cooling System

Cooling the strip plate fast to control the crystallinity of plastics, which can guarantee the elongation when the strip plate is pulled.

Main technical parameters:

Material: stainless steel.

Rise-and-fall adjustable

Temperature control system

6Drying Device

Main technical parameters:

Motor power: 1.5kw

Rotate speed: 3800r/min

7The Five Rollers Haul-off

Used to pull the strip plate, it is composed of five rollers.

Main technical parameters:

Inverter control, chain transmission

Motor power: 3kw

Speed: 2-80 m/min

Roller diameter: 268mm

Roller length: 250mm

8Heating Oven

Used to preheat strip plate again after the first pulling

Main technical parameters

Length: 3000mm

Heating power: 18kw

Material: stainless steel

9Preheating and Haul-off

Used for the strip preheated traction stretch and the preheating again. This machine is composed of five preheating rollers, and the form is multistep. There is large contact area between rollers. The preheating effect is excellent, and the preheating adopts thermocouple heating.

Main technical parameters:

Inverter control, chain transmission

Motor power: 5.5kw

Heating power: 7.5kw

Roller diameter: 268mm

Roller length: 250mm

Traction speed: 1-40 m/min

10The Five Roller Haul-off

It is composed of five preheating rollers. The form is multistep.

Main technical parameters

Inverter control, chain transmission

Motor power: 7.5kw

Heating power: 7.5kw

Roller diameter: 268mm

Roller length: 250mm

Hauling linear velocity: 20-150m/min

11Embossing Machine

The material of the embossing roller is 38CrMnAl/A, nitriding treatment, emboss

Clear, good abrasion resistance

Main technical parameters:

Material: 38CrMoAlA

Motor power: 2.2kw

12Hot Shaping Machine with Cooling Tank

Used to finalize the design rapidly after the second pulling and stretching for the ideal effect.

Main technical parameters:

Length: 3000mm

Heating power: 12kw

Material: stainless steel

13Drying Device

Main technical parameters:

Motor power: 1.5kw

Rotate speed: 3800r/min

14The Three Rollers Haul-off

Used for the traction after finalizing the design. It is composed of three steel rollers.

Main technical parameters:

Inverter control, chain transmission

Motor power: 4kw

Roller diameter: 268mm

Roller length: 250mm

Traction linear velocity: 20-150 m/min

15Winder 1 set

Main technical parameters:

Spindle control: torque motor

Control mode: torque motor controller

Driving mode: gear

Winding diameter: 406mm

Torque motor: YLJ100-5/6

Output torque: 5N.M

16Control system

Complete all parts and compound the operation control of the production line. Each component can be managed effectively

Main technical parameters:

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for Best quality Plastic Pulverizing Machine - PET PP strap packing tape extrusion line – Cuishi , The product will supply to all over the world, such as: Bolivia, India, South Korea, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!